At Skillcraft, our customers rely on our expertise and equipment to produce high-quality components and parts that meet their exacting requirements. That’s why we utilize CNC Turning as a manufacturing process.

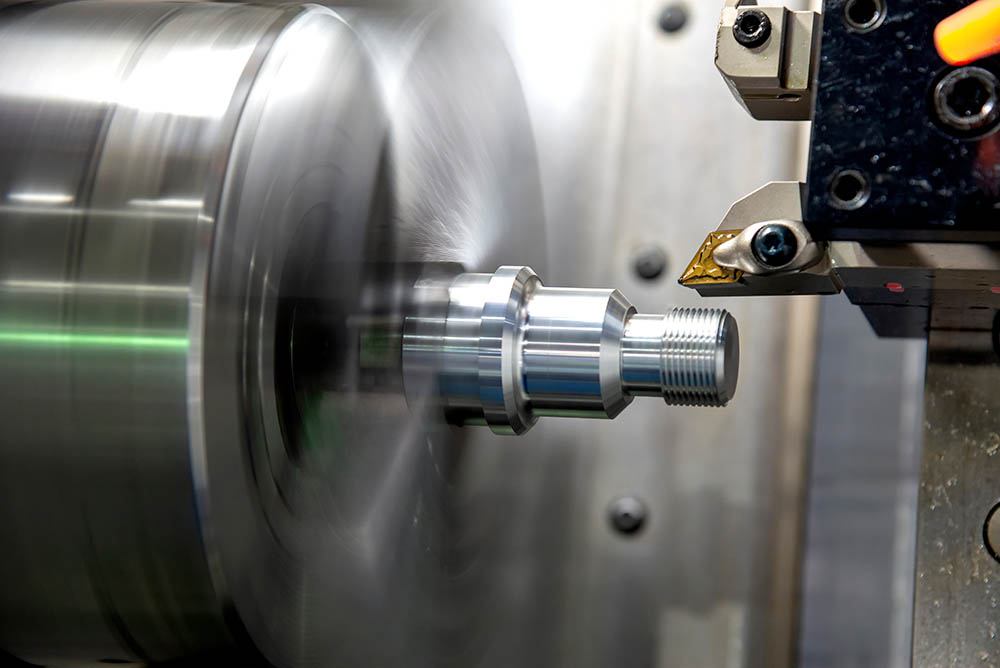

Computer Numerical Control (CNC) turning is a machining process that enables us to turn solid pieces of metal into precision components for larger assemblies and equipment. The CNC machinery holds the piece of metal in a chuck and rotates it for cutting and shaping.

A turret of tools and different cutting and shaping bits remove material until the metal piece is the specified shape. The turrets and bit selection are controlled by a program created by Skillcraft to fit the exacting needs of the component.

This manufacturing process is sometimes called “subtraction machining” because it involves the removal of material. However, there is a key difference between our CNC machines and other subtractive machines. In many subtractive machines (i.e. water jets, plasma cutters, laser cutters) the workpiece is secured to a bed while the tool head moves across the workpiece to do the cutting. However, our CNC turning process does the reverse. Our computer-controlled machine rotates the workpiece and cuts away at it through the movement of a static cutting piece.

We can help you determine if CNC Turning is the right choice for your precision part. Give Skillcraft a call today, and let us know how we can help you.

- (1) HURCO TMX8i

- (1) HURCO TM12i

- (1) ProtoTrak 1630

- (1) ProtoTrak 1845

- (1) ProtoTrak 2460

- (1) Fryer ET-25

Maximum Work Envelope

25” diameter x 60” length

Our customers reply on our expertise and equipment to produce high quality components and parts that meet their exacting requirements. Contact us to learn how we can help you.